Msc: Sustainable Engineering : Chemical and Process Engineering

Results obtained from Simulation

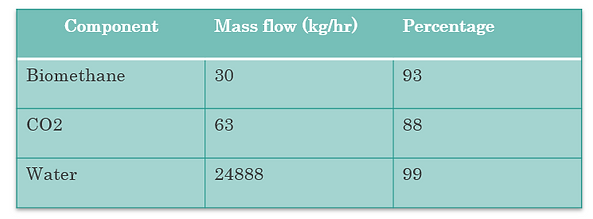

Table 1: Flowrates obtained from the Simulation

The Aspen simulation exhibits the upgrading process production efficiency of biomethane of 30 kg/hr purity 93%, which is presented as the outlet stream containing removed impurities such as CO2 indicating suitability of biomethane for energy production or as a vehicle fuelThe captured CO2 is observed at a rate of 63 kg/hr with an 88% capture rate, implying a significant part of CO2 is successfully separated and could possibly be used in applications such as enhanced oil recovery or carbonation in the beverage industry. As a result, the stream can be defined by an amazing water usage of 24,888 kg/hr with a recycling percentage of 99% reiterating the overall values of the system's sustainability as it minimizes fresh water demand while maximizing recirculation within the water scrubbing setup. This outcome confirms the fact that the SBP technology treats the gas to a very high purity, captures CO2 and at the same time optimizes water use, therefore, it is an economically viable and environmentally friendly solution.

Table 2: Results obtained from Aspen Simulation

Result obtained in different composition

The simulation results illustrate a clear trend: the initial methane content in the biogas feed is a key factor that influences the purity of the biomethane produced, making it crucial to optimize the biogas composition to achieve the desired level of methane uptake. This data will assist operational adjustments and feedstock system which is able to produce optimum biomethane yield and quality, this will improve the general efficiency of biogas upgrading. This information is crucial to operators of biomethane and other industries trying to make use of a cleaner energy source, for the goal of optimization (Rotunno et al., 2017).